Aguila WIM / WILD

Weighing in motion / Wheel impact load detection

Description

The wheels of railway vehicles are subjected to extreme stress and strains inevitably leading to wear and tear. Flat sections, as well as damage to the contact areas, are typical indicators of deterioration. The immediate result of this wear and tear is greater variation in the vertical forces between the wheel and the rail.

Aguila (WILD/WIM) is a system designed to detect flat patches, eccentric wheels, and other wheel damage potentially destroying railway infrastructure (WILD) as the smooth running of the train is impaired, potentially giving rise to overheated hot boxes, damaging monitoring systems installed on the tracks. Aguila monitors the wheels of the railway coaches, checking to ensure they rotate in a true circle; if they fail to do so, corresponding messages are reported to the control room. This system can also serve as a dynamic weighbridge (WIM).

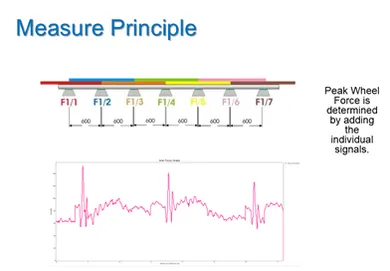

The measurement principle is based on track-mounted sensors using unique fiber optic technology. The system directly measures the force exerted by the wheels on the rail with the values obtained directly from between the sleeper and the rails. Thanks to the sensor location and the unique direct measurement principle, there are NO blind spots – not even above the sleepers – and regardless of the diameter of the wheels.

The AGUILA WIM/WILD System can be installed on Metro lines, freight lines (bearing heavy haulage trains), classic lines, as well as high speed lines.

Summary of the benefits offered by AGUILA system:

- Low installation overhead

- The use of fiber optic sensors minimizes installation overhead: the sensor is

placed between the rail and the sleeper in an easy procedure.

Both installation and maintenance can be carried out quickly in any kind of weather. - Safety

- AGUILA ensures reliable detection of damage to the contact area because the system continuously monitors the entire circumference of the wheels.

- Easy-to-maintain

- De-installing the system for tamping is not necessary.

- Versatile

- Aside from monitoring flat wheels, the AGUILA system can also be used as a

dynamic weighbridge.

Technical Data

- Detection of all kind of wheel defects (eccentric wheels, flat sections, etc )

- Fiber Optic Technology ( immune against electromagnetic interference)

- Unique measurement principle. The systems directly measures force at origin ( no indirect measurement using bending of rail)

- No blind points thanks to unique measurement principle, independently of wheel diameter.

- Simple to install and maintain (installation within 1 day)

- Wheel loads of up to 40t

- Records train weight, and monitors overloads and asymmetrical loads

- Train weight reproducibility: +/- 1 till 3%

- Packable (tamping of the ballast without de-installation of the sensors)

- Integrated Ballast analysis System (BAS)

- Integrated auto-calibration and self-check functions

- Max. number of axles: 3000

- Speed range 5-400km/h

- Measure lenghth from 4 -48 F-sensors (2,4m-28,8m , at sleeper distance of 0,6m)

- Unique and stable positioning of F-sensors between sleeper and rail (sensors cannot slip or be displaced).

- Peak Force measurement up to 650KN

- Compliant with norms EN 55011:98 + A 1:99 + A2:02, Class B (Emissions Test),EN 50121-4:00 (EMC), EN 15654-1:2015

- Development according to EN50128

- Automatic identification of locomotives, wagons and train compositions.